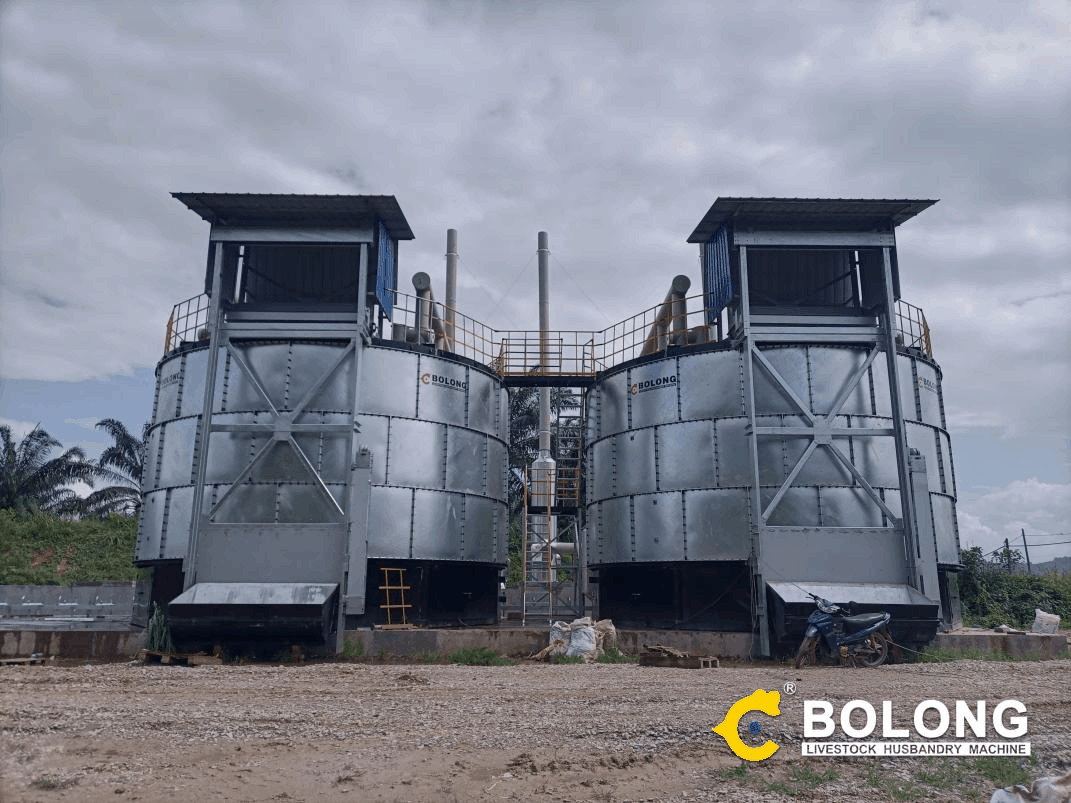

There are 11 types of compost tank produced by Bolong, which can meet the needs of different scale breeding enterprises. Among them, Model 280 is the largest daily processing capacity of our company’s compost tanks, and it is also the largest compost tank on the market at present, which is in the leading position in the industry.

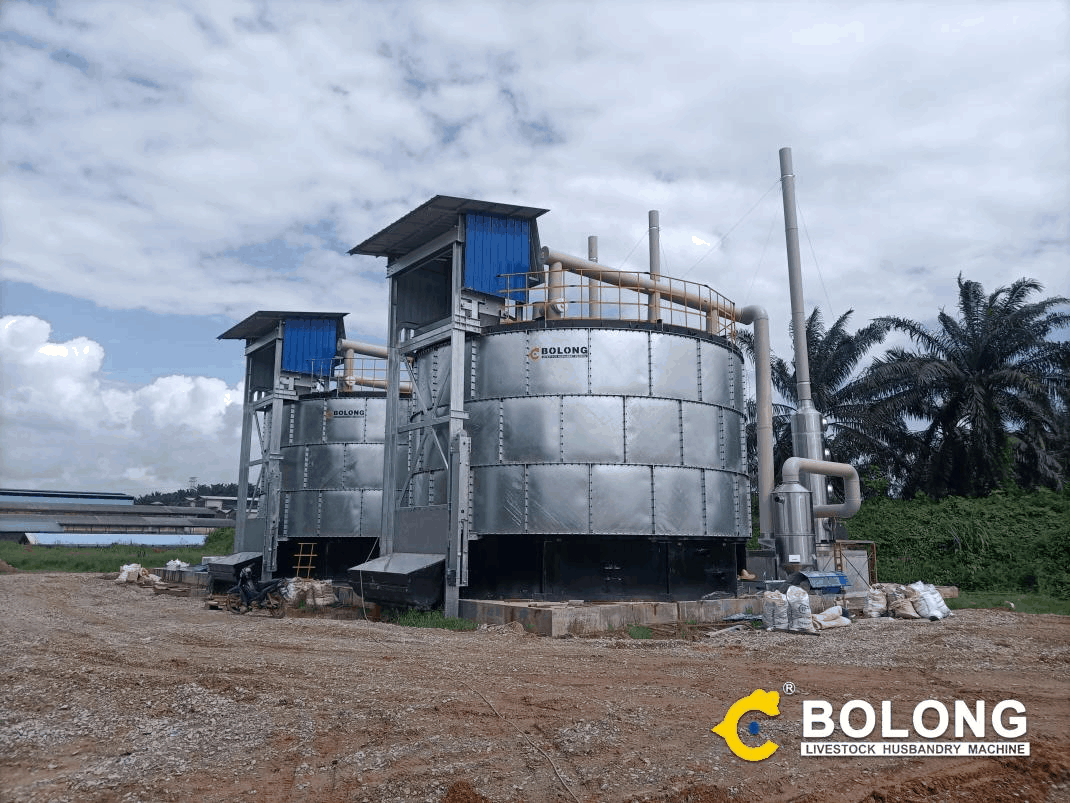

Product principle: The equipment adopts the aerobic matter and fermentation principle of aerobic microorganisms,so that the microorganisms use the organic matter and residual protein in livestock and poultry manure and kitchen waste to rapidly multiply under a certain temperature,humidity and sufficient oxygen environment,thereby realizing the organic waste Harmless treatment.

Function: The tank can compost organic waste into organic fertilizer in 7 days.

Raw materials: The compost tank suitable to dispose animal manure, food waste,vegetables and fruits, sewage sludge, mushroom etc. Chicken manure is good raw material for the tank.

Capacity: One set 280 model compost tank can process approximately 20-28m³ waste per day and produce 8-12m³ organic fertilizer.

Shape: Vertical

Footprint: 100㎡

Instruction:Fully automatic operation.We just need to put the waste into the autohopper, and press the button of the controller. The hopper will be lift automatically and throw the waste into the tank. You just wait for the finally products, organic fertilizer.

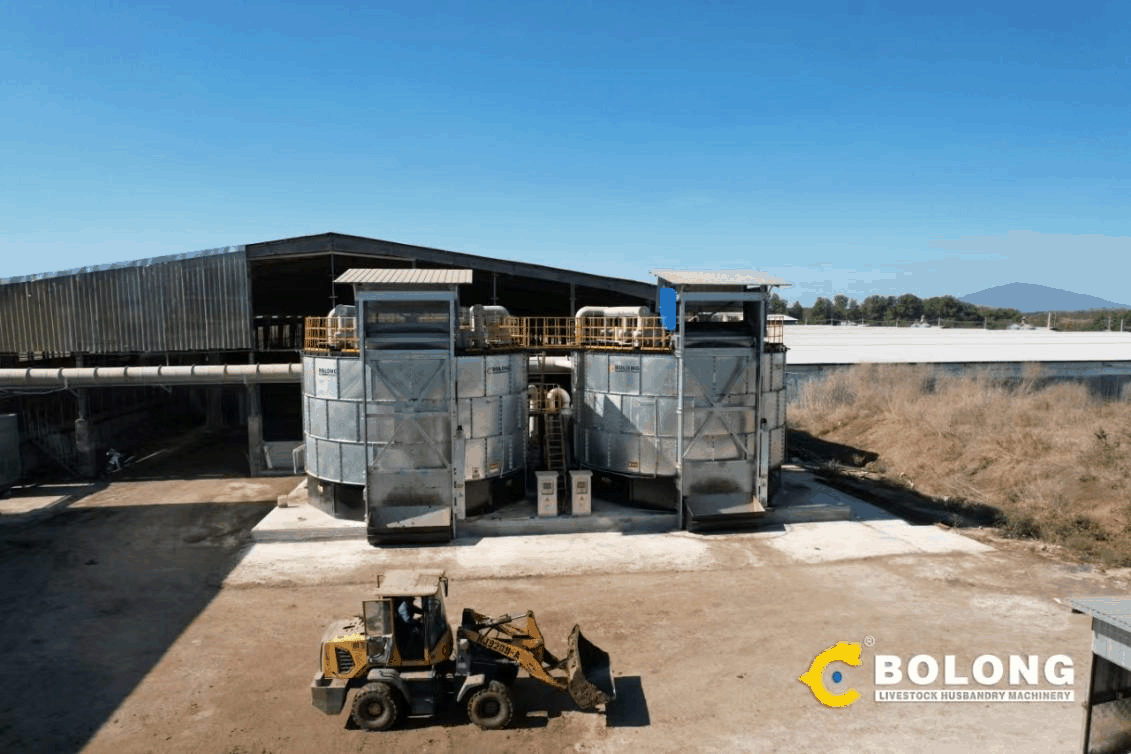

280 Compost Tank has been running smoothly in our own factory since it was built and put into operation. With the help of the 280 Compost Tank, the production efficiency of the Bolong plant is constantly increasing. Last summer, our clerk contacted a customer in Vietnam.The customer is the boss of a large layer chicken farm in Vietnam (hereinafter referred to as Mr. Phong), we all know that Vietnam is located in the tropics, livestock and poultry waste is not professionally treated, and it is easy to breed bacteria in a high temperature environment, and the unpleasant taste is not good to deal with, which will pose a serious threat to the livestock and poultry in the farm. Mr. Phong has found many ways to deal with this, and the results were not satisfactory.By chance, Mr. Phong learned about the product of high-temperature aerobic fermenter and began to investigate those industries. But because the processing capacity is too large, the compost tanks on the market can not meet the needs of Mr. phong’s farm. Our clerk met Phong at an exhibition, and after understanding the relevant demands, we recommended our new product 280 compost tank and our patented gas deodorization system to him. Mr. Phong was very interested in hearing this, and our clerk invited Mr. Phong to visit the Bolong factory, and the two met in China two months later.

During this period, our clerk also kept introducing our products to Mr. Phong. Finally, in the fall, we welcomed Mr. Phong and his team. During the visit, Mr. Phong was very satisfied with the production environment of our factory, he said that the 280 Compost Tank can well meet the needs of his large farm, and the gas deodorization system has solved his major concerns. On the spot, we reached a cooperation intention and Mr. Phong ordered two 280 compost tank and gas deodorization systems. Subsequently, Mr. Phong also paid promptly, and we hastened the delivery and sent technicians to Mr. Phong’s factory to guide the installation. Some time ago, our clerk asked Mr. Phong about the operation status of 280 compost tank, Mr. Phong said that he was very satisfied, and said that he would buy 8 sets of 280 compost tank in the future (the deposit has been paid), and also recommended the Bolong compost tank to his friends.

Since 280 was put into use, it has been widely praised in the market, after all the quality of Bolong has reached a first-class level.Mr. Phong as the first to use 280 compost tank, and now his farm is thriving under the support of Bolong 280 compost tanks.Hereon,many doubts are also broken.