Efficient commercial composting equipment designed for high-temperature, high-humidity, and water-scarce regions. Reduce odor, prevent leachate, and produce organic fertilizer in 7 days.

As a specialist manufacturer of organic fertiliser fermentation equipment, we understand that with today’s increasingly stringent food hygiene and agricultural standards, ensuring hygiene and sanitation standards in the fermentation process has become a key concern for farmers. Therefore, we design and manufacture our high temperature aerobic fermenters with hygiene and safety as the primary considerations to provide our customers with hygienic and safe fermentation solutions.

Our fermenters adopt advanced automatic sterilisation system, which can regularly sterilise the inside of the tank at high temperature during the fermentation process, effectively eliminating the growth of various bacteria and viruses. We have also adopted an airtight design to ensure that the fermentation materials are not contaminated by the outside world during the whole process.In addition, our fermenter is equipped with a highly efficient filtration system, which can effectively block all kinds of bacteria, fungi and other impurity particles, ensuring that the organic fertiliser produced during the fermentation process meets the hygiene standards and provides safe and reliable products for the end-users.

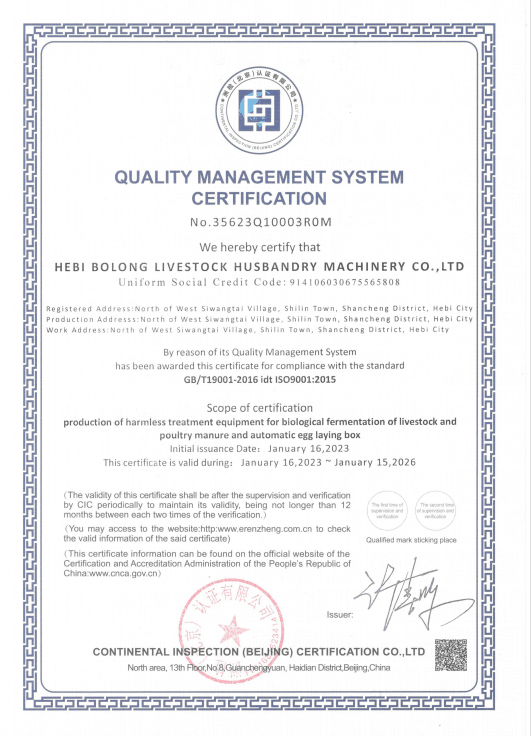

Our fermentation equipment is designed and manufactured in strict compliance with internationally recognised food-grade hygiene standards, including ISO22000, HACCP, etc., to ensure that the equipment itself and the organic fertiliser it produces are in full compliance with globally accepted safety and hygiene requirements.At the same time, we also equip the equipment with an independent quality testing module, which can monitor and analyse the key indicators in the fermentation process in real time, provide timely warning of faults and system tuning recommendations to ensure that the whole process is hygienic and of the highest quality.Our professional service team will also provide systematic training and guidance to our customers to help them master the correct operation and maintenance of the equipment to ensure that the hygiene standards of the fermentation process are continuously and effectively implemented and controlled.

As a professional organic fertiliser equipment supplier, we have always adhered to the development concept of health and safety first, and are committed to creating safer and more reliable fermentation solutions for our customers. We believe that only through strict health control, we can create safer and healthier organic fertiliser products for farmers and help the sustainable development of green agriculture.

Let’s work together to write a new chapter of organic fertiliser industry!

Efficient commercial composting equipment designed for high-temperature, high-humidity, and water-scarce regions. Reduce odor, prevent leachate, and produce organic fertilizer in 7 days.

Bolong’s high-temperature aerobic fermentation tank converts manure to organic fertilizer in 7 days. A closed-loop, eco-friendly solution for large farms in the Middle East. Achieve compliance & boost profit.

Discover how Bolong’s automatic egg collector reduces broken/dirty eggs, improves hatchability, supports animal welfare, and boosts efficiency for African poultry farms.