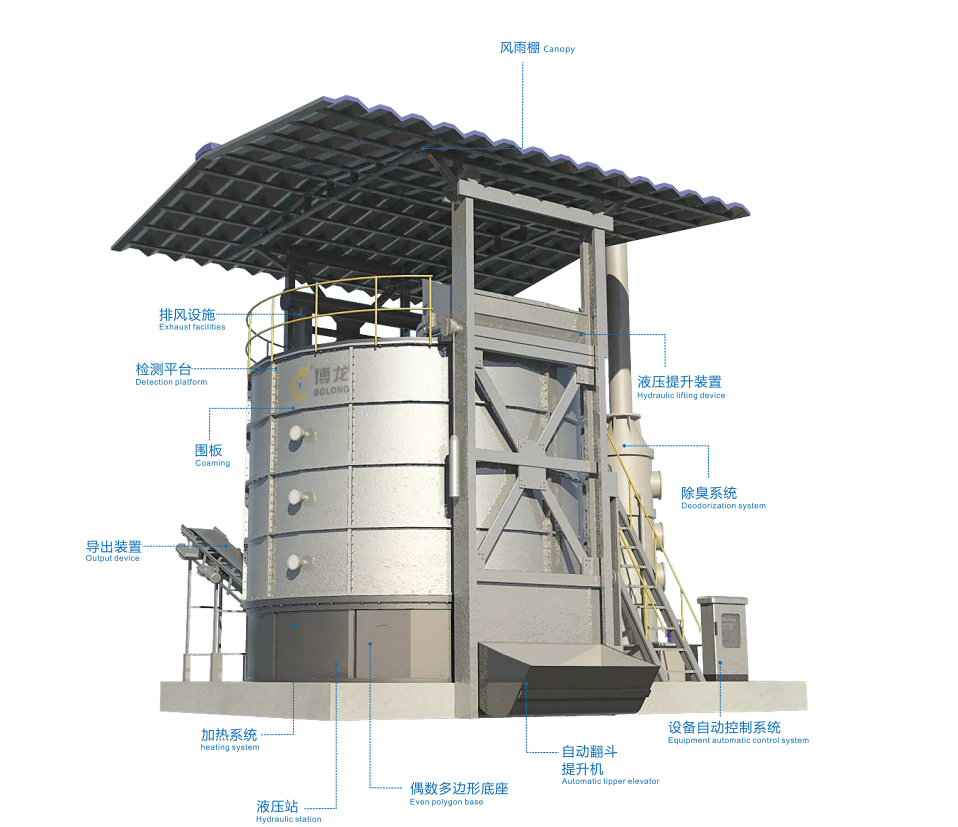

Bonglong High-temperature Aerobic Compost Tank

High-temperature aerobic compost tank is our self-developed environmental protection equipment, the equipment uses the decomposition of microorganisms in nature, after 7 days of continuous aerobic fermentation in a closed tank, organic solid waste through microbial fermentation, deodorization, putrefaction and other roles into organic fertilizers that can be used for crops, aerobic fermentation is a less malodorous, energy-saving method of obtaining treatment of organic fertilizers.

Equipment Introduction

“Bolong” brand High-temperature Aerobic Compost Tank is suitable for different humidity broiler, egg chicken manure, moisture as long as within 50% ~ 70%, without adding any auxiliary materials, can be directly into the tank, the equipment can adapt to the high humidity, high cold in different geographical areas, the use of vertical closed tank structure, reducing the installation of the The equipment can adapt to different regions with high humidity and high cold. The equipment adopts aerobic microorganism aerobic fermentation principle, so that the microorganisms use the organic matter, residual protein, etc. in livestock and poultry faeces and carcasses, and reproduce rapidly under a certain temperature, humidity and sufficient oxygen environmental conditions, so as to achieve the harmless treatment of livestock and poultry wastes.

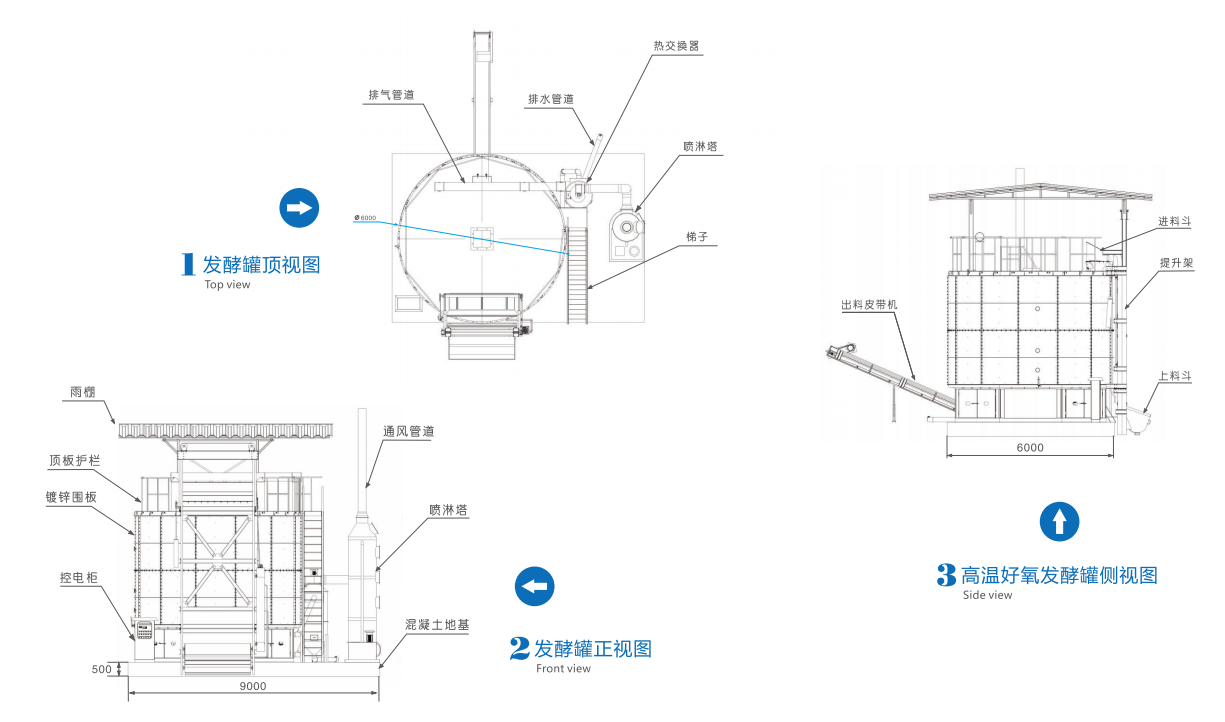

It is a continuous system where waste can be put in every day and organic fertiliser is produced every day. The bucket elevator lifts the organic waste and automatically places it into the (tank). The organic waste is mixed in the tank by means of mixing blades. A special heat exchanger uses the heat of the waste gases to heat up fresh air and bring it into the tank, where the hot air is blown through holes in the blades. The warm air accelerates the aerobic fermentation and evaporation of water from the organic waste, which is converted into high-quality organic fertilizer after an average of seven days.

The whole equipment structure is divided into three parts, the lower part of the base part of the distribution of hydraulic stations, scroll air pumps, cylinders, heating systems and mixing shafts, etc.: the middle of the double-layer insulated tanks, equipment, automatic control systems, export devices, etc., the inner wall of the tank is lined with 304 stainless steel plate, effectively extending the life of the tank and reduce the residue of rotting matte, the middle of the polyurethane foam filled with thermal insulation, the outer wall of the thickening of the steel sheet as a support! Tank body: the upper part is composed of storm shelter, testing platform and exhaust facilities and other devices. Attached equipment are automatic bucket elevator, exhaust gas filtering and deodorizing system and heat exchange system.

After-sales Service

Ltd. in line with the “user satisfaction is the success of the Bolong” business philosophy, in addition to the use of advanced and reliable equipment, reasonable and perfect technology and other hardware, but also a complete means of training, high-quality service system as a back-up, to ensure that the Bolong machinery built the quality of the project, and at the same time reduce the production of energy consumption and maintenance costs! In order to make users invincible in the fierce market competition.

Warranty period service commitment.

National Customer Service Hotline:400 800 9989