May 17, 2019 · Large scale In tank composting, which makes high quality compost through the use of enclosed “reactors” that closely monitor temperature and oxygen levels throughout the biodegradation of organic materials, is popular.

May 17, 2019 · Large scale In tank composting, which makes high quality compost through the use of enclosed “reactors” that closely monitor temperature and oxygen levels throughout the biodegradation of organic materials, is popular.

Our range of In tank Rocket food waste composters. The Rocket Composter is a robust, high quality machine that processes commercial scale food waste and green waste on site, using natures own process of composting. Invented by Tidy Planet and now in its 20 th year of manufacturing, there are over 1,000 machines in operation across the globe.

The Rocket® technology allows for a continuous In tank process in a cost effective way, saving time and effort, while producing high quality compost. The end product is compost, its a finish product which only needs to be cure in the open air where there is no need to aerate during this curing process.

The design for the high flow In tank drum composter was born from a desire to find the most affordable and efficient way to compost mixed food waste, in a way that produces high quality soil amendments on an institutional scale. Download the operating manual here.

Aug 29, 2016 · In tank composting can process large amounts of waste without taking up as much space as the windrow method and it can accommodate virtually any type of organic waste (e.g., meat, animal manure, biosolids, food scraps). This method involves feeding organic materials into a drum, silo, concrete-lined trench, or similar equipment.

The BIOvator® is the only all-stainless steel, In tank composter on the market in successful operation in more than 1000 locations Worldwide. Free of any plastic drum material that can warp and wear. The BIOvator® has been strategically engineered with stainless steel and has been tested for unmatched durability and function.

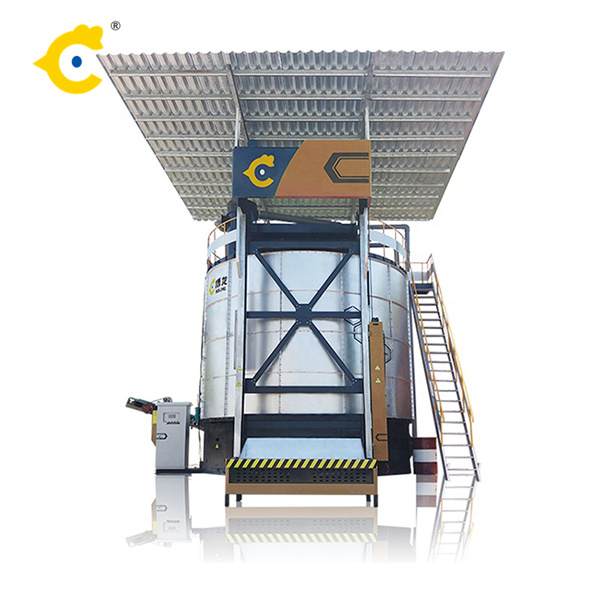

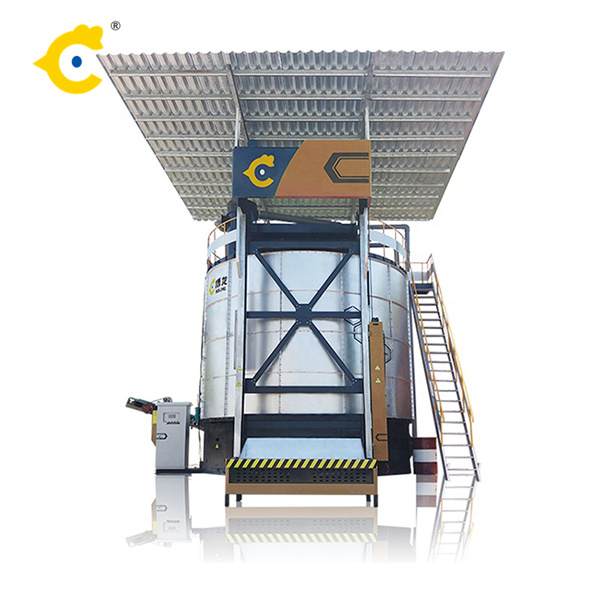

The cost of In tank composting system from SEEC mainly involve the following three aspects: composting equipment purchase cost, energy consumption, maintenance cost. If you want to do In tank composting or start a business of In tank composting, the most important thing you have to do is choosing a high quality composting equipment.

Sep 30, 2015 · FOR Solutions owners say the system includes an on-site aerobic In tank rotary drum digester that protects the environment by recycling food waste into high-quality compost in five days. FOR Solutions composters are optimized for large institutions such as colleges, nonprofits and mid-to-large size businesses that currently send large amounts

Jul 6, 2023 · The increasing generation of biodegradable solid waste has generated significant interest in decentralized In tank composting as an alternative to centralized systems. An optimized waste decomposer microbial formulation, comprising Bacillus cereus C1 and Aspergillus niger P-19 selected for their ability to produce multiple carbohydrases, was prepared using a low-cost medium. The capsular

May 5, 2023 · The specificity of the vessel design allows for optimal composting conditions, including temperature, aeration, and moisture control. This results in a higher-quality compost free of pathogens and weed seeds. The success of vessel composting can be seen in its widespread adoption by businesses, schools, and communities worldwide.

Learn how the BIOvator® In tank composter brings your waste back to life in less than two weeks and can compost up to 1500lbs of organic waste everyday. Leaving you with a nutrient rich compost material, ready to use on-site. This method outproduces traditional composting in a safer more effective way to help stop the spread of disease

We have the expertise and agility to build, own or operate alternative waste treatment facilities in Australia. Our waste treatment technologies include In tank (tunnel), windrow and aerated static pile composting, and anaerobic digestion (wet and dry). At the heart of Western Composting Technology (WCT) is the Geelong-based Dickens family

Dec 12, 2023 · Windrow composting often requires equipment such as front-end loaders, excavators, or windrow turners. In tank. In tank composting can process a variety of organic materials without taking up much space. This method involves feeding materials into a vessel, such as a drum, silo, concrete-lined trench, or similar enclosed equipment.

Oct 7, 2022 · Mari et al. revealed that elemental sulphur (S o) can be employed to avoid excessively high pH levels during composting. C/N ratio and organic carbon. The C/N ratio is an essential indicator in evaluating the start-up and determining the effectiveness of a composting process and the quality of compost produced.

In tank composter bedding recovery system processes manure on a 5,500-cow dairy to produce a unique high-comfort fiber bedding that increases hygiene and reduces costs. Project Goal: • Evaluate manure fiber bedding technology to replace chopped straw and sawdust bedding • Increase cow comfort and hygiene • Reduce cost and take