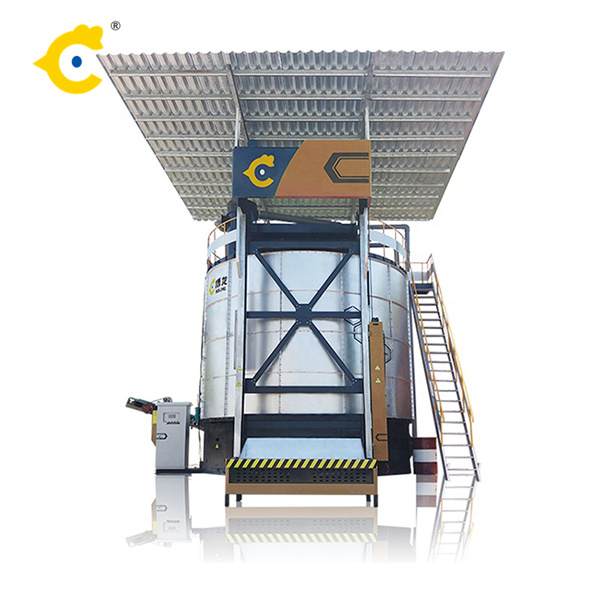

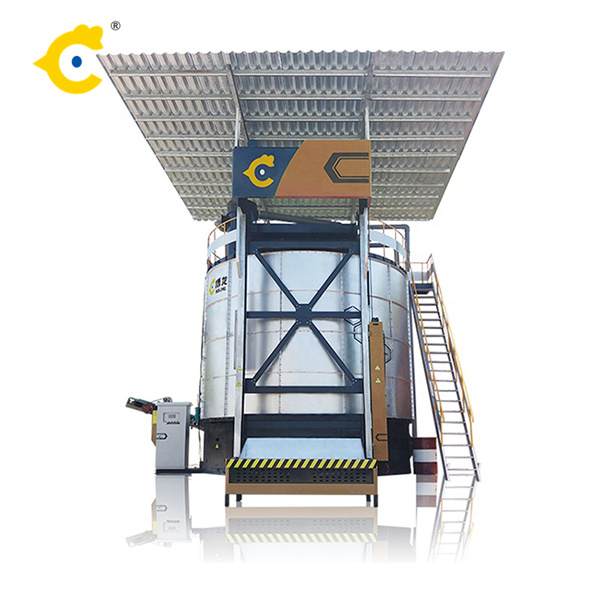

Fermentation Tank Fertilizer Machine Organic Compost Manufacturing Machines. Model Number:11FFG-145. Power: 40-45 KW. Samples: 11FFG-90 25-30 KW. Customization: Customized logo (Min. order 5 sets) GET QUOTE.

Fermentation Tank Fertilizer Machine Organic Compost Manufacturing Machines. Model Number:11FFG-145. Power: 40-45 KW. Samples: 11FFG-90 25-30 KW. Customization: Customized logo (Min. order 5 sets) GET QUOTE.

However, our fermentation tank makes it possible to finish the process of composting within half a month, even in the winter. Despite its outstanding features, our fertilizer compost vessel is not a perfect machine for every organic fertilizer plant, particularly one on a large scale.

There are several types of composting machines available, including groove-type compost turners, crawler-type composting devices, and fermentation tanks. Each has its advantages and limitations, and the choice depends on the scale of chicken poop and available working space.

Among these machines, the organic fertilizer production equipment mainly consists of compost making machine and machines for deep processing (crushing, screening, granulating, packaging). On the hand, Shunxin commits to design and produce manure to fertilizer machines, so as to fully utilize organic waste and create green life.

Fermentation Tank for Sale; Fully Automatic Composting Machine; How to Make Chicken Poop Compost; Large Scale Compost Turner Machine; Windrow Composting equipment; Organic Waste Composting Machine; organic waste composting machine; Poultry Manure Composting Process; Sludge Composting; Small Scale Compost Turner; Granulators. Pan Pelletizer

Specialize in Organic Fertilizer Production. ABC Machinery is a leading manufacturer of organic fertilizer production with CE & ISO certifications. We specializes in the design, development, and production of large-scale equipment such as fermentation tanks, and fertilizer granulators. ABC machinery provide customized solution for organic

Pre-treatment—prepare chicken manure and adjust fermentation conditions. During composting, auxiliary materials are also necessary as well as chicken manure. Auxiliary materials, like straw, sawdust, pin shavings, are used for adjusting C/N ratio and moisture of compost piles. You should add proper crushed straw to adjust C/N ratio to 25:1-30:1.

Apr 2, 2024 · The size of the tank can significantly impact the fermentation process, with larger tanks often used for commercial production and smaller tanks preferred by craft brewers and home winemakers. The 100-gallon fermentation tank strikes a balance between capacity and manageability, making it ideal for small to medium-scale production. Benefits of

A chicken manure fermentation tank is a specialized container designed for the controlled decomposition of chicken manure. It provides an optimal environment for the breakdown of organic matter through microbial activity. The tank facilitates the transformation of raw chicken manure into a stabilized and nutrient-rich organic fertilizer.

Due to special design and apparatus, SEEC fully automatic composting machine can finish composting in 7 to 10 days. What’ more, this equipment can complete sterilization and deodorization in 10 hours. The volume of automatic composter ranges from 5m 3 to 150 m 3. Besides multiple volumes and short composting period, it is space-saving and

Nov 1, 2015 · This article discusses many of the problems that can arise related to large-scale industrial fermentation vessels (that is, those with a capacity up to 1 million gal) that are increasingly being used for industrial bioprocesses. It also presents recommendations for appropriate CIP and sterilization design for large-scale systems.

This fermentation tank is designed with all major parts made of SUS304 Stainless steel material, ensuring durability and safety. It also comes with a 1mm thickness liquid tank of full 65 liters capacity, making it easy to store and use. Additionally, it’s suitable for fermenting various kinds of wine/beer/fruit enzyme.

The main structures of fermentation tank include body, mixer, air supply system, material lifting device, control cabinet, hydraulic power station, biological deodorization equipment and sensors of temperature and oxygen concentration. Mixer: The mixer is fixed inside the fermentation tank. It is used for stirring organic waste to realize

Apr 10, 2018 · Lager fermenters are generally three to four times shorter in their diameter than the height and use an operation pressure of 1–1.5 bar. European fermentation tanks for lager beer commonly use shorter tanks with a diameter-to-height ratio of <2:1, which causes fermentation to equalize more completely than in horizontal vessels.

The crawler type chicken poop compost turner is a large-scale turning equipment for processing your stacked chicken manure. It is also a multi-functional turning machine that integrates fermentation, mixing, crushing and shifting.