GET PRICE. Animal Manure Fertilizer Fermentation Tank for Sale. The Animal manure fermentation tank can process organic fertilizer processing of different livestock and poultry manure, food waste, domestic sludge, etc.

GET PRICE. Animal Manure Fertilizer Fermentation Tank for Sale. The Animal manure fermentation tank can process organic fertilizer processing of different livestock and poultry manure, food waste, domestic sludge, etc.

The Dungster has patented a high-efficiency, In tank, aeration composting system ideal for manure management and other biodegradable waste management projects. With a locally sourced dumpster and a Dungster Composting Kit, delivered by courier to your door, you can be . Top 4 Animal Manure Composting - Fertilizer Plant Cost

Jan 5, 2022 · Also look at the upper tank, which should be constructed with waterproof materials, and it should also have an automatic bucket elevator and heat exchange system. After assessing all of the ones that you can find, you will eventually locate the very best animal manure fermentation tank for this exact purpose.

The moisture content should be controlled at 50%-75% during fermentation. High Temperature. 50-70℃ is the ideal temperature for aerobic reproduction. Our fully automatic composting machine can keep the temperature between 50℃-65℃ and last about 5 days. Abundance Oxygen.

Sep 15, 2023 · The high manufacturing cost of biobutanol and the toxic effect of the product on bacterial cells restrict the market-oriented production of butanol, so the development of high-efficiency and high-tolerance strains and the research on product separation technology have received widespread attention (Fangxia et al., 2019; Heap et al., 2007).

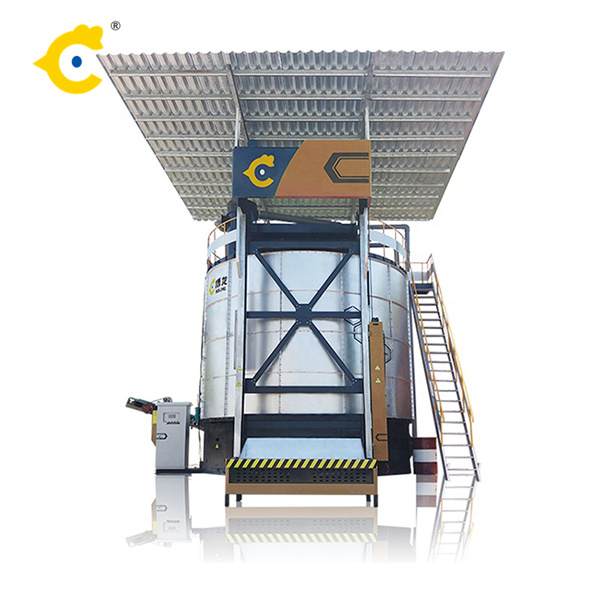

Organic manure vertical fermentation tank designed by FPC company with 100-200m³ processing capacity. Manure fermentaion finished in 7days. FPC vertical type manure fermentation tank is an advanced organic fertilizer production machine.

Sep 30, 2021 · A common fermentation is to build a fermentation tank. The manure will be decomposed into biogas and biogas slurry after fermentation in the fermentation tank. The biogascan be used as fuel, and the biogas slurry can be used as fertilizer, which can reduce the use of chemical fertilizers. The improvement is also very good.

Aug 1, 2023 · The cow manure was collected from a local dairy farm in Lanzhou, China. The total solid (TS) and volatile solid (VS) of cow manure was measured. Cow manure samples were used as AD substrates. The batch reactors were 250 mL glass bottles with a working volume of 200 mL. The cow manure substrate itself was used as the inoculum in the AD system.

Jan 2, 2024 · One hundred fifty tons of liquid manure was fermented in a liquid manure tank by an air ring blower at 0.03–0.045 m 3-air/min·m 3, and 14 t of solid manure was fermented in a solid manure

FertilizerProductionProject. Loading your Organic Material. High-temperature Ferment and Decompost Material. Feeding your Fermented Material. Placing your Material. Get A Free Quote. 5 reasons for buying organic fertilizer fermentation tank. Small in Size. Sealed Treatment. the Insulation. Operation. Energy.

Technical Specialist. +31 (0)6 51576194. +31 (0)58 2999 913. vanderveen@jongia.com. Manure Fermentation A guide to enhance biogas production Manure is one of the most abundant agricultural waste products, and it has been used for a long time.

Successful Case of Fermentation Tanks. High-temperature aerobic fermentation tanks are designed to create the best environment for the decomposition of organic matter, including pig manure, cow manure, sheep manure, chicken manure, etc. The aerobic microbial fermentation process enables microorganisms to break down and utilize the residual

Dry Fermentation of organic waste and manure. Dry fermentation (SSAD) in a biogas plant involves the fermentation of organic feedstocks to produce biogas under anaerobic conditions (without atmospheric oxygen). The solid fermentation plant consists of drivable, gas-tight, and acid-resistant concrete fermenter boxes, which are filled and emptied

A fermentation tank is a cylindrical container that has a rotating shaft inside. The shaft is equipped with blades that can stir and mix the manure with air and microorganisms. The tank also has a heating system that can maintain the optimal temperature for the composting process. The fermentation tank can automatically control the moisture

Jan 19, 2024 · Beer Fermentation Tank Sizes. Beer fermentation tanks cover a wide range of sizes from a few barrels to massive volumes over 1000 barrels. Some typical fermenter capacities include: Pilot Systems: 1-3 BBL; Microbreweries: 3-7 BBL, 7-30 BBL; Pub Breweries: 15-30 BBL; Production Breweries: 30-300 BBL, 600-800 BBL, 1000+ BBL