An organic fertilizer fermentation tank is a specialized container or vessel designed for the controlled decomposition and fermentation of organic materials, such as agricultural waste, manure, and plant residues.

An organic fertilizer fermentation tank is a specialized container or vessel designed for the controlled decomposition and fermentation of organic materials, such as agricultural waste, manure, and plant residues.

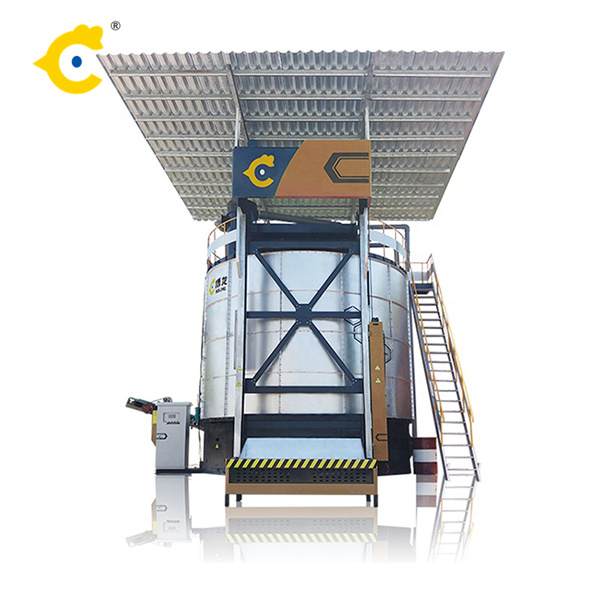

Organic Fertilizer Production Poultry Manure Compost Tanks Fermentation Equipment, Find Details and Price about Fermentation Tank Fermentation Tank for Sale from Organic Fertilizer Production Poultry Manure Compost Tanks Fermentation Equipment - Henan Tongda Heavy Industry Science And Technology Co., Ltd.

High-temperature aerobic fermentation tanks are designed to create the best environment for the decomposition of organic matter, including pig manure, cow manure, sheep manure, chicken manure, etc. The aerobic microbial fermentation process enables microorganisms to break down and utilize the residual proteins in these organic materials, converting the waste into organic fertilizer.

If you want to compost animal manure (such as composting pig manure, cow dung composting and horse manure composting), you need to do the following works, including collect manure (and bedding) from barn, make a compost pile and turn them regularly until fermentation finishes. The detailed process is as below:

The fermentation times are relatively short in fertiliser fermenters. In the conventional method, composting organic matter with a turner takes about 20 days. The first fermentation process in a manure fermentation tank will last about 7 days, after which the production of organic fertiliser can be carried out every day.

Scope of Application of Poultry Manure Aerobic Fermentation Tank In Vessel Compost Turner High temperature aerobic fermentor Sludge Fermentation Tank Bio organic fertilizer fermentor 1. Livestock and poultry manure: chicken manure, cow, sheep, horse manure, rabbit manure, etc. 2. Agricultural waste: such as straw, soybean meal, cotton meal, etc. 3.

ABC Machinery offers 0.3-10tph organic fertilizer production line solutions and specializes in organic fertilizer production equipment, including fermentation tanks, compost turners, fertilizer granulators, etc. Get a quick inquiry!

Our products are widely used in the treatment of chicken manure, pig manure, duck manure, cow manure, as well as sludge and kitchen waste. We have a fecal cleaning system, aerobic fermentation tank, pumping system, and can also customize according to different customer needs.

This review article presented the current status and traditional agricultural waste (livestock manure and crop straws) utilization , the art of aerobic fermentation process including ultrahigh temperature fermentation and composting.

The Livestock and Poultry Manure Fermentation Tank is a versatile solution capable of efficiently processing a wide range of organic materials, including animal manure and animal carcasses from various sources such as chickens, pigs, cattle, sheep, and horses.

The fermentation times are relatively short in fertiliser fermenters. In the conventional method, composting organic matter with a turner takes about 20 days. The first fermentation process in a manure fermentation tank will last about 7 days, after which the production of organic fertiliser can be carried out every day.

10000L(10T) Fermentation Tank is a Modular cylindrically-conical tank consist of a base tank (BT) and expansion accessories (valves, fittings, armatures, tools ) By choosing and using various types of expansion accessories, it is possible to assemble the tank in several configurations that are optimal for the desired part of the production process.

The Animal manure fermentation tank can process organic fertilizer processing of different livestock and poultry manure, food waste, domestic sludge, etc. As long as the moisture content of organic waste is below 65%, there is no need to add any auxiliary materials and it can be put directly into the tank.

The equipment adopts the aerobic fermentation principle of aerobic microorganisms, so that the microorganisms use the organic matter and residual protein in livestock and poultry manure and kitchen waste to rapidly multiply under a certain temperature, hums and sufficient oxygen environment, there realizing the organic waste Harmless treatment.

Manure Fermentation Tank Model:11FFG-116Total height:Dia 5600mm Height10050mm(Equipped with a rain shelter)Equipment weight:30TCover an area:40m2Effective volume:100m³Daily processing capacity:10-12m³/dayDaily output:3-4m³/hPower supply:380V 50HZTotal power:54.5KWOperating power:Around 27KW Organic Fertilizer Fermentation System *Tank organic fertilizer fermentation system, or fermenter