Feb 18, 2023 · Therefore, if poultry manure is fermented in an air-tight bag in an anaerobic condition with a fermentation mixture of PM (90%) and molasses (10%) inoculating 10% IMO at least for 7 days, it can

Feb 18, 2023 · Therefore, if poultry manure is fermented in an air-tight bag in an anaerobic condition with a fermentation mixture of PM (90%) and molasses (10%) inoculating 10% IMO at least for 7 days, it can

Jun 4, 2018 · This paper performs a batch experiment for pre-acidification treatment and methane production. from chicken manure by the two- stage anaerobic fermentation process. Results shows that the acetate

Nov 12, 2021 · The chicken manure humidity can be decreased from 70 to 30%, and the effective control system temperature is between 40 and 42 °C, while the pH value is changed from 8.7 to 7.4. The sample

Jan 20, 2021 · Method One: The fermentation bacteria should be added to chicken manure and mixed well. And an appropriate amount of rice bran or corn and bran also be added according to the situation. Then you should stir them evenly and sprinkle them into the prepared materials. The amount of water contained in chicken manure should be appropriate.

Jun 1, 2013 · Annually, about 13 million tons of chicken manure (CM) is generated in Japan, which corresponds to 0.65 times the total food processing waste (MAFF, 2008). Since the organic matter in CM is highly biodegradable, methane fermentation is considered the best method to minimize waste and recover bioenergy.

Manure composting systems help you compost fast. Shunxin adopts odorless fermentation tech and provides customized hydraulic type turner for you.

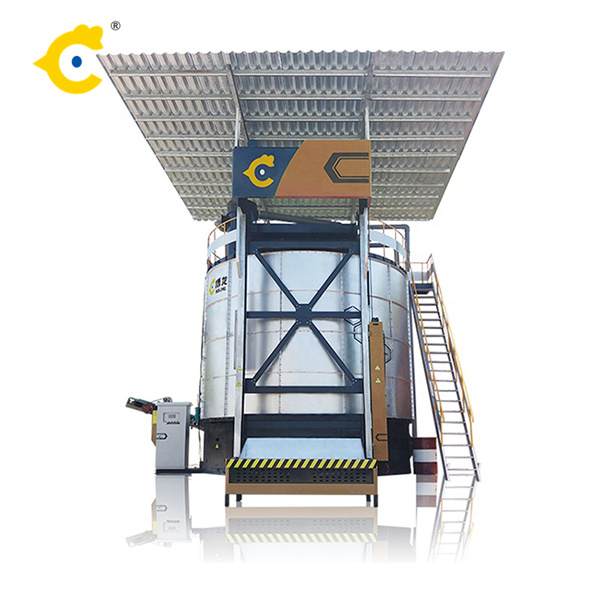

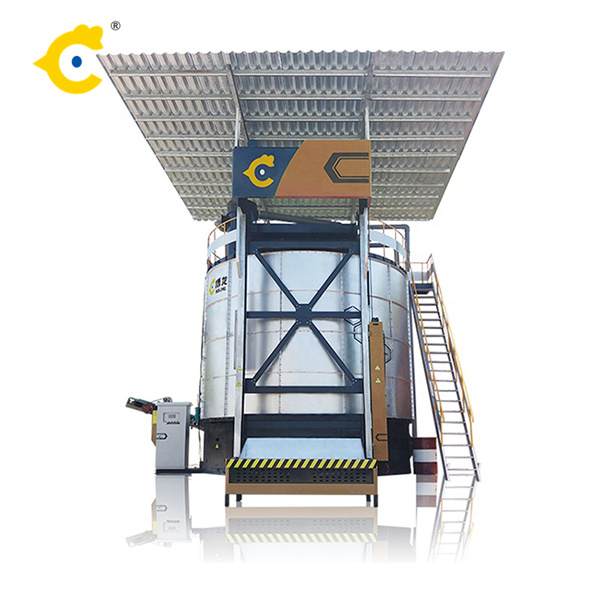

The fermentation equipment can be used for treating organic waste such as pig manure, chicken manure, cow dung, sheep manure, mushroom residue, Chinese medicine residue, crop straw, etc., occupying less land (fermentation machine only covers 10-30 m2), no pollution (Closed fermentation), completely killing pests and eggs (can be adjusted to 60

Nov 12, 2021 · This research aims to build a smart solar chicken manure fermentation system to control the conditions of chicken manure fermentation effectively, improve quality, and solve the problems of environmental pollution.

May 15, 2014 · Thermophilic fermentation has been applied to many cases, such as sludge, municipal solid waste, cattle manure, poultry manure and corn grain ethanol industry waste treatment [4], [5], [6]. Compared with the mesophilic process, however, the thermophilic process is more sensitive to changes in pH, VFA, ammonia and toxic substrates.

The fermentation equipment is suitable for producing organic fertilizer. Through this equipment, you can turn pig manure , chicken manure and cattle manure into fertilizer. And these manure is from some farms. So why do some farmers choose this equipment?

Dec 15, 2023 · December 15, 2023. News. There are two types of organic fertilizer tanks: horizontal and vertical. Horizontal Fermentation Tank: The process begins by uniformly mixing collected manure in the fertilizer box and then pumping it into a dry-wet separation pretreatment machine within the system.

Jul 15, 2023 · The present study aimed to evaluate the anaerobic co-digestion process of chicken manure and corn stover to identify the key parameters that influence methane production. Results from both batch and semi-continuous tests showed that co-digestion enhanced methane production, with an optimal chicken manure to corn stover ratio of 2:1 under experimental conditions. When this ratio was maintained

The Livestock and Poultry Manure Fermentation Tank is a versatile solution capable of efficiently processing a wide range of organic materials, including animal manure and animal carcasses from various sources such as chickens, pigs, cattle, sheep, and horses.

What is a Chicken Manure Fermentation Tank? A chicken manure fermentation tank is a specialized container designed for the controlled decomposition of chicken manure. It provides an optimal environment for the breakdown of organic matter through microbial activity.

Jun 12, 2023 · Adopting waste-to-wealth strategies and circular economy models can help reduce biowaste and add value. For instance, poultry farming is an essential source of protein, and chicken manure can be converted into renewable energy through anaerobic digestion. However, there are a number of restrictions that prevent the utilization of chicken manure in bioenergy production. Here, we review the