Nov 1, 2014 · Cow dung and urine have been used as natural fertilizers and pesticides for centuries in India and recent scientific research has confirmed their effectiveness in promoting sustainable

Nov 1, 2014 · Cow dung and urine have been used as natural fertilizers and pesticides for centuries in India and recent scientific research has confirmed their effectiveness in promoting sustainable

Jan 4, 2023 · Of course. For one thing, you can use professional compost equipment in cow dung fermentation. It will turn cow manure regularly to supply enough oxygen and dissipate excessive heat timely. They can greatly facilitate aerobic fermentation of cow manure. For another, you can add fermentation bacteria to cow dung, which can promote the

Jun 11, 2019 · In general, if you want to make organic fertilizer from cow dung, you need to dispose of cow manure with the following steps. Including dewatering, composting, crushing, mixing, granulation, drying, cooling, coating and packaging.

Oct 19, 2020 · It is recommended to be equipped with an automatic return system to screen out unqualified large and small pellets and send them through a belt elevator to the new type organic fertilizer granulator to continue pelletizing after being crushed again, which will help improve the continuous operation capacity of the cow dung organic fertilizer production line.

Dry Fermentation for High Solid Percentage Organic Waste Cow Dung Dry Fermentation technology differs from traditional "wet digester" tank systems that utilize liquid feedstock and physically stir and agitate materials with moving parts. During the fermentation process, no further mixing, pumping or stirring is necessary inside the digester

Top 2 processes of making bio fertilizer from cow manure (cara membuat biofertilizer) Converting cow manure to bio fertilizer is a win-win choice for you. On the one hand, you can dispose of the cow manure waste in your farms. On the other hand, making cow manure into bio fertilizer can increase your income.

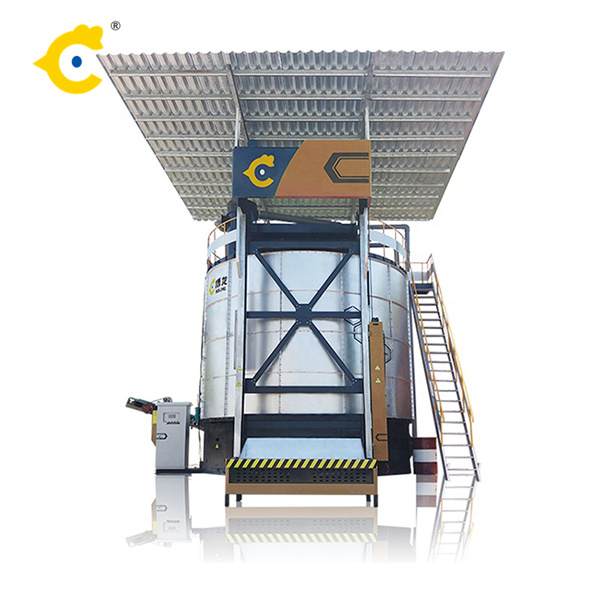

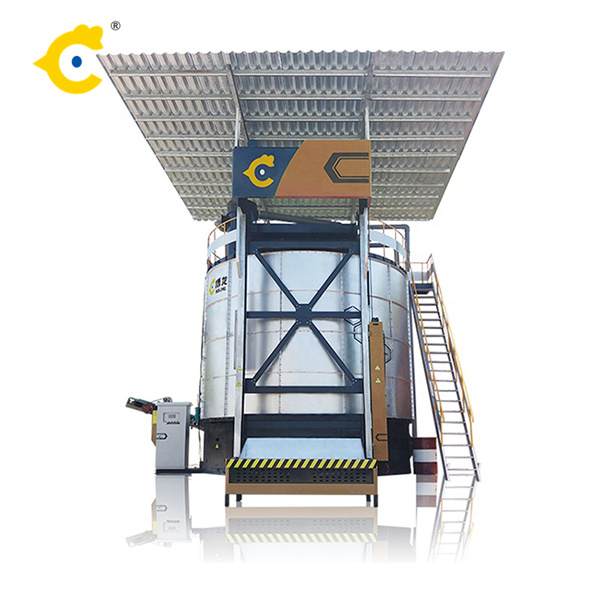

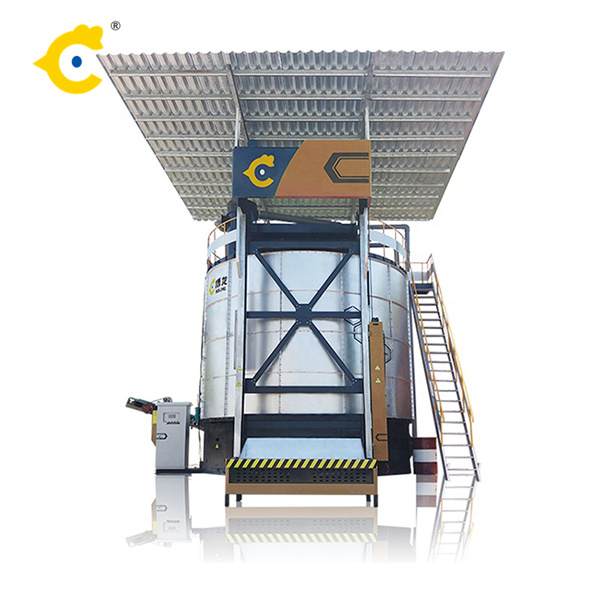

Jul 27, 2023 · Traditional cow manure composting equipment often lacks ventilation, heating, and real-time monitoring and adjustment capabilities, hindering manure maturation and proper utilization of compost, moisture reduction, and optimal environmental conditions for microbial activity. To address these limitations, we optimized and redesigned the structure and control elements of conventional composting

Dec 15, 2023 · Depending on whether the material is used as organic fertilizer or bedding material, the fermentation time ranges from 7 to 24 hours. After fermentation, the residue is directly conveyed out of the fermentation tank. Dry or wet cow dung can be added directly to the organic fertilizer fermentation tank.

Dec 1, 2021 · The update research on CD microflora and CD in agricultural domain such as biocontrol, growth promotion, organic fertilizer, sulfur oxidation, phosphorus solubilization, zinc mobilization and underlying mechanisms involved in these processes are discussed.

First fermentation 1. First, the cow dung should be dried or drained to keep its moisture content below 85%. 2. Then add carbon auxiliary materials, such as peanut shell powder, sawdust powder, and the ratio of cow dung to auxiliary materials is 8:2, so that the carbon ratio of raw materials (cow dung) and auxiliary materials (straw powder) is controlled at 23-28, and the water content is

Dec 4, 2018 · Making cow dung into organic manure is one of the main to treat cow dung. Dry cow dung contains 10%-20% crude protein, 1%-3% crude fat, 20%-30% nitrogen-free extract and 15%-30% crude fiber, so it has high nutrients.

Furthermore, after putting cow manure and other materials into fermentation tank, you just need set parameters on the PLC control system, and will get cow dung compost in 7-10 days. Besides above-mentioned apparatus, there is stirring apparatus, which can regularly turn the materials and send air by holes on it.

Sep 30, 2020 · The treatments each year 2017 and 2018 consisted of: rabbit manure, cow dung, poultry manure, green manure [Mexican sunflower (Tithonia diversifolia Asteraceae)], pig manure, NPK 15-15-15

Jul 14, 2021 · This study aimed to determine the optimal conditions for producing Moringa organic fertilizer (MOF) from previously unused parts and to compare these fertilizers with cow manure and bio-organic

Raw material for biogas (cow dung (a), pulp (b), and fermentation washing water (c)) and biogas burning (d). Biogas production was done by mixing (± 20 rpm) the pulp material with cow dung, washing water with cow dung, and cow dung with water (Figure 3a–c). Each mixture was added with Em-4 microbe